Org. Synth. 2023, 100, 304-326

DOI: 10.15227/orgsyn.100.0304

Synthesis of a Furoindoline Scaffold via an Interrupted Fischer Indolization

Submitted by Georgia M. Scherer, Jordan Gonzalez, Laura G. Wonilowicz, and Neil K. Garg*

1Checked by Yu-Hin Ho, Zengsheng Yin, and Pauline Chiu

1. Procedure (Note 1)

A. 3-Methyltetrahydrofuran-2-ol (2). A single-necked (24/40 joint) 1000-mL round-bottomed flask, charged with a Teflon-coated magnetic stir bar (5 x 1 cm, football-shaped), and a 125 mL pressure-equalizing addition funnel (24/40 joint) are dried in an oven overnight (160 ℃). The glassware is assembled while hot, and the addition funnel is sealed with a 24/40 rubber septum with an argon inlet and an outlet connected to a bubbler. The apparatus is allowed to cool to 23 ℃ under a stream of dry argon. The joint between the addition funnel and round-bottomed flask is wrapped tightly with Teflon tape and clamped with a Keck clip (24/40) (Note 2). 3-Methyldihydrofuran-2(3H)-one (1) (3.3 mL, 3.52 g, 35.2 mmol, 1.0 equiv) (Note 3) is added to the addition funnel through the septum using a plastic syringe, and the solvent is dispensed into the round-bottomed flask. Dry methylene chloride (42 mL, 0.83 M) (Note 4) is then added through the septum via a plastic syringe, and this rinsing is dispensed into the round-bottomed flask. The solution is cooled to -78 ℃ in a dry ice-acetone bath and stirred for 30 min (250 rpm). Diisobutylaluminum hydride in hexanes (1.0 M, 38 mL, 38 mmol, 1.1 equiv) (Note 5) is transferred to the addition funnel via a plastic syringe, then dispensed into the flask dropwise over 15 min. Once the addition is complete, an additional 5 mL of methylene chloride is added to the addition funnel as a rinse, and dispensed into the reaction mixture over 1 min. The reaction is stirred (250 rpm) at -78 ℃ for 2 h under a positive pressure of argon (Note 6) (Figure 1).

Figure 1. Reaction setup (photo provided by submitters)

After 2 h, the reaction is quenched at -78 ℃ by the dropwise addition of acetone (3.0 mL) dispensed from the addition funnel (Note 7) over two min while stirring (150 rpm). The apparatus is removed from the dry ice-acetone bath, and allowed to warm to 23 ℃ over 20 min by placing in a water bath at ambient temperature while stirring (250 rpm). The reaction mixture is opened to the air, and poured into a single-necked (24/40 joint) 1000-mL round-bottomed flask containing a stir bar (4 x 1.5 cm, football-shaped) and saturated aqueous Na-K tartrate (350 mL) (Note 8), rinsing the reaction flask with methylene chloride (2 x 10 mL). The 1000-mL round-bottomed flask is then fitted with a septum that is pierced with an argon inlet and gas outlet. The resulting mixture is stirred vigorously (550 rpm) at 23 ℃ for 2 h until both the aqueous and organic layers are no longer cloudy (Figure 2).

Figure 2. Na-K tartrate and reaction mixture after 2 h of stirring (photo provided by checkers)

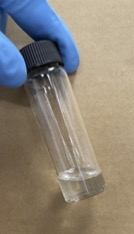

The aqueous and organic layers are transferred to a 1000 mL separatory funnel. The round-bottomed flask is washed with diethyl ether (30 mL) (Note 9), and this solvent is added to the separatory funnel. The upper organic layer is separated without shaking. The aqueous layer is extracted with diethyl ether (3 x 200 mL). The organic layers are combined, dried over anhydrous Na2SO4 (88.4 g) (Note 10), and filtered through a sintered glass funnel (7 x 7 cm, 150 mL) into a 1000 mL round-bottomed flask. The funnel is rinsed with diethyl ether (2 x 50 mL), and the filtrate is concentrated on a rotary evaporator under reduced pressure (30 ℃, 760 mmHg to 120 mmHg) (Note 11). The resulting 3-methyltetrahydrofuran-2-ol (2) (3.06 g, 63% purity by 1H NMR analysis) is obtained as a clear and colorless oil (Figure 3) (Notes 11, 12, 13, 14, 15, 16, and 17), which is used directly in the next step without further purification (Note 18).

Figure 3. Crude 3-methyltetrahydrofuran-2-ol (2) (photo provided by checkers)

B. 3a-Methyl-3,3a,8,8a-tetrahydro-2H-furo[2,3-b]indole (4). A single-necked (24/40 joint) 500-mL round-bottomed flask is charged with a Teflon-coated magnetic stir bar (4 x 1.5 cm, football-shaped). 3-Methyltetrahydrofuran-2-ol (2) (3.06 g,18.9 mmol based on 63% purity, 1.0 equiv) is added using a glass pipette, rinsing with diethyl ether (2 x 2 mL) to ensure quantitative transfer. Glacial acetic acid:deionized water (1:1) (174 mL, 0.20 M) (Note 19) is then poured into the flask via a graduated cylinder, followed by the addition of phenylhydrazine (3) (3.40 mL, 35 mmol, 1.8 equiv) to the open flask over 5 min using a plastic syringe (Note 20). The flask is fitted with a condenser (20 cm, 14/20 joint). The flask to condenser joint is sealed with Teflon tape, and secured with a Keck clip (24/40). The condenser is cooled by running water, the flask is placed in an oil bath preheated to 60 ℃, and the solution is stirred open to air at 250 rpm for 4 h (Figure 4) (Note 21).

Figure 4. Reaction setup (photo provided by checkers)

After 4 h (Note 22), the apparatus is removed from the oil bath and allowed to cool to 23 ℃. The contents of the flask are transferred to a 250-mL separatory funnel, which is positioned to drain into a pre-cooled 1000-mL Erlenmeyer flask containing saturated aqueous sodium bicarbonate (400 mL), an additional 100 g of solid sodium bicarbonate (Note 23), and a stir bar (5 x 1.5 cm, oblong) (Figure 5). The reaction flask is rinsed with water (2 x 10 mL), and the washings are added to the addition funnel (Note 24).

Figure 5. Reaction set up for slow addition of reaction mixture to saturated aqueous sodium bicarbonate (photo provided by checkers)

The reaction mixture is dispensed from the funnel into the Erlenmeyer flask dropwise over 20 min, while the contents of the flask are stirred at 550 rpm. After all of the reaction mixture is added, additional solid sodium bicarbonate (120 g) is slowly added in portions, until the solution reaches a pH of 7. The resulting mixture is allowed to warm to 23 ℃, and an additional 100 mL of water is added and stirred. The stir bar is removed, and the contents of the flask are transferred to a separatory funnel (1000 mL). Ethyl acetate (2 x 50 mL) is used to rinse the flask, and the rinses are added to the funnel. The contents of the separatory funnel are extracted with ethyl acetate (3 x 200 mL) (Note 24). The organic layers are combined and washed with brine (200 mL) (Note 25). The organic layer is collected, dried over anhydrous Na2SO4 (74 g), and filtered through a sintered glass funnel (7 x 7 cm, 150 mL) under vacuum (75 mmHg). The sintered glass funnel is washed with ethyl acetate (2 x 50 mL). The organic layers are collected in a 2000 mL round-bottomed flask and concentrated on a rotary evaporator (30 ℃, 760 mmHg to 30 mmHg).

Diethyl ether (100 mL) is added to the concentrated crude reaction mixture. Activated charcoal (6.5 g) (Note 26) is added, and the solution is swirled by hand for 30 sec. Celite (12 g) (Note 27) is added to the round-bottomed flask, and the flask contents are filtered under vacuum (75 mmHg) through a sintered glass funnel (7 x 7 cm, 150 mL) packed with celite (34 g). The round-bottomed flask is rinsed with diethyl ether (4 x 50 mL), which is also filtered over the celite pad. The filtrate is collected in a 500 mL round-bottomed flask and concentrated using a rotary evaporator under reduced pressure (30 ℃, 750 mmHg to 30 mmHg) (Figure 6).

Figure 6. Concentrated crude reaction mixture before and after treatment with activated charcoal (photo provided by checkers)

A column (6 cm OD x 22.1 cm tall) is prepared using silica gel (231 g) that is wetted with hexanes (1000 mL) (Notes 13 and 28). The concentrated crude mixture is loaded onto the column, and the flask is rinsed with methylene chloride (3 x 5 mL). The rinses are also loaded onto the column (Figure 7).

Figure 7. Column with crude material loaded (photo provided by checkers)

The column is then eluted with 10% ethyl acetate in hexanes. The fractions are collected in 50 mL test tubes, and the desired product is found in fractions 38-64 (Notes 29 and 30). These fractions are pooled and concentrated under reduced pressure (760 mmHg to 30 mmHg, 30 ℃). The resulting oil is then transferred to an 8-dram vial and dried under high vacuum (8 mmHg) for 1 h (Note 31), to afford the desired product 3a-methyl-3,3a,8,8a-tetrahydro-2H-furo[2,3-b]indole (4) as a pale-yellow oil (3.71 g, 98.5% purity, 60% yield) (Notes 32, 33, and 34). Storage in a -20 ℃ freezer overnight yielded a pale yellow solid after warming to room temperature (Figure 8).

Figure 8. Isolated 3a-methyl-3,3a,8,8a-tetrahydro-2H-furo[2,3-b]indole (4) (photo provided by checkers)

2. Notes

1. Prior to performing each reaction, a thorough hazard analysis and risk assessment should be carried out with regard to each chemical substance and experimental operation on the scale planned and in the context of the laboratory where the procedures will be carried out. Guidelines for carrying out risk assessments and for analyzing the hazards associated with chemicals can be found in references such as Chapter 4 of "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at

https://www.nap.edu/catalog/12654/prudent-practices-in-the-laboratory-handling-and-management-of-chemical. See also "Identifying and Evaluating Hazards in Research Laboratories" (American Chemical Society, 2015) which is available via the associated website "Hazard Assessment in Research Laboratories" at

https://www.acs.org/content/acs/en/about/governance/committees/chemicalsafety/hazard-assessment.html. In the case of this procedure, the risk assessment should include (but not necessarily be limited to) an evaluation of the potential hazards associated with

α-methyl-γ-butyrolactone,

methylene chloride,

i-Bu2AlH,

benzene,

ethyl acetate,

acetone, deionized

H2O,

Na-K tartrate tetrahydrate,

1,3,5-trimethoxybenzene,

acetic acid,

phenylhydrazine,

sodium bicarbonate,

hexanes,

diethyl ether, activated charcoal, celite, silica gel and

CDCl3.

2. The submitters flame-dried the 1000 mL round-bottomed flask equipped with a Teflon stir bar and the addition funnel under vacuum, then cooled the apparatus to 23 ℃ under an atmosphere of

nitrogen. The addition funnel is sealed with a 24/40 rubber septum with a

nitrogen inlet equipped with an outlet connected to a bubbler, and the flask is flushed with

nitrogen for 5 min. The joint between the addition funnel and round-bottomed flask is wrapped tightly with Teflon tape and clamped with a Keck clip (24/40). The submitters conducted the synthesis under an atmosphere of

nitrogen.

3. Both the submitters and checkers used

3-methyldihydrofuran-2(3H)-one (

1) (98%) purchased from Sigma-Aldrich Corp., which was used as received. The checkers added 3.3 mL of

1 by syringe, and the mass of

1 added was determined by weighing the filled syringe before and after the injection.

4. The checkers used

methylene chloride (99.9%) purchased from Duksan Pure Chemicals. It was passed through a drying alumina column in a PureSolv MD 5 Solvent Purification System before use. The submitters used

methylene chloride (99.9%) purchased from Fisher Chemical. It was passed through an activated alumina column before use.

5. The checkers used

diisobutylaluminum hydride (

i-Bu2AlH, 1.0 M in

hexanes) purchased from J&K Scientific. A brand-new, unopened bottle was used as received. The submitters used

i-Bu2AlH (1.0 M in

hexanes) purchased from Sigma-Aldrich Corp. which was transferred to the graduated addition funnel via a cannula.

6. The progress of the reaction is monitored by TLC analysis on silica gel plates (Figure 9) using 2:1

benzene:

EtOAc as eluent. The plates are visualized using a phosphomolybdic acid (PMA) stain. Lactone

1 has R

f 0.86 (UV inactive, white spot), and the lactol product (

2) has R

f 0.56 (UV inactive, blue-green spot). A TLC plate developed using a

ρ-anisaldehyde (PA) stain is also shown on the right. A reaction TLC plate developed using an alternative eluent of 2:1

hexane:

EtOAc is provided for comparison (Figure 10).

Figure 9. TLC of the reaction mixture after 2 h, developed using 2:1 PhH:EtOAc (Sm = lactone 1, and Rxn = reaction mixture, and C = co-spot of 1 and Rxn) (photo provided by checkers)

Figure 10. TLC of the reaction mixture after 2 h, developed using 2:1 Hexane:EtOAc (photo provided by checkers)

7. The checkers used

acetone (99.5%) which was purchased from RCI Labscan Limited and used as received. The submitters used

acetone (99.5%) purchased from Fisher Chemical, which was used as received.

8. The checkers used

Na-K tartrate tetrahydrate purchased from TCI Chemicals, which was used as received.

Na-K tartrate tetrahydrate (175 g) is added to 350 mL of deionized water to make the saturated aqueous solution. The submitters used

Na-K tartrate tetrahydrate purchased from the Sigma-Aldrich Corp., which was used as received.

9. The checkers used

diethyl ether (99%) was purchased from RCI Labscan Limited and used as received. The submitters used

diethyl ether (99%), purchased from Fisher Chemical, which was used as received.

10. The checkers used anhydrous

Na2SO4 (>99%) purchased from Dieckmann Chemicals, which was used as received. The submitters used

Na2SO4 (>99%) purchased from Sigma-Aldrich Corp., which was used as received.

11. A small sample (~10 mg) of the crude material was dried under high vacuum (0.05 mmHg) for NMR analysis. The rest of the material was not dried under high vacuum, as the product is volatile. The purity was determined to be approximately 63% by qNMR

pdf using

1,3,5-trimethoxybenzene (Sigma-Aldrich, >99.9%) as the internal standard.

12. A 130 mg sample of crude

2 was purified by column chromatography using a 1.8 cm OD x 15 cm tall column containing 10.5 g of silica gel (

Note 13) and wetted with 100 mL

hexane (

Note 14). The sample was eluted with 4:1

hexanes:

EtOAc (300 mL,

Note 15) and collected in 20 mL test tubes. The desired product

2 was found in fractions 7-11 (Figure 11). Fractions containing the product are identified by TLC analysis using 2:1

hexanes:

EtOAc as the eluent. The plates are visualized using phosphomolybdic acid stain. Compound

2 has an R

f of 0.33 (UV inactive, blue-green spot). The fractions containing

2 are pooled together, and each test tube is rinsed with (2 x 1 mL)

diethyl ether (

Note 9), to ensure quantitative transfer. The collected material was concentrated under reduced pressure (30 ℃, 500-100 mmHg).

Figure 11. TLC analysis showing column fractions (photo provided by checkers)

13. The checkers used Silica gel 60 (particle size 0.040-0.063 nm) purchased from Millipore Merck, which was used as received. The submitters used SiliaFlask P60 (particle size 0.040-0.063 nm) purchased from SiliCycle and used as received.

14. The checkers used

hexanes (GR grade) purchased from Duksan Pure Chemicals, which was used as received. The submitters used

benzene (99.0%) purchased from Sigma-Aldrich Corp., which was used as received.

15. The checkers used

ethyl acetate (99.5%) purchased from Duksan Pure Chemicals, which was used as received. The submitters used

ethyl acetate (99.5%) from Fischer Scientific, which was used as received.

16. The purity of product

2 obtained from chromatography was determined to be >96% by qNMR

pdf using

1,3,5-trimethoxybenzene (Sigma-Aldrich, >99.9%) as the internal standard.

17. Characterization data of purified

2: (2:1 mixture of diastereomers),

1H NMR

pdf (500 MHz,

CDCl3)

δ:5.09 (5.26) (d,

J = 3.2 Hz, 1H), 4.06 - 4.01 (4.12 - 4.07) (m, 1H), 3.95 (3.80) (dd,

J = 13.6, 7.9 Hz, 1H), 3.15 - 2.97 (2.94- 2.78) (m, 1H), 2.25 - 2.16 (2.14 - 1.95) (m, 2H), 1.57 - 1.47 (1.78 - 1.64) (m, 1H), 1.09 (1.02) (d,

J = 6.8 Hz, 3H).

13C NMR

pdf (126 MHz,

CDCl3)

δ: 104.4 (99.3), 67.4 (67.1), 40.6 (38.7), 31.7 (30.8), 17.3 (12.9); IR (film): 3427, 3174, 1653, 1069, 910 cm

-1; HRMS-EI (

m/z) [M]

+ calcd for C

5H

10O

2, 102.0681; found, 102.0674; R

f (2:1

hexanes:

EtOAc) 0.33. The submitters determined the boiling point to be 72-76 ℃ at 22 mmHg. A second reaction of the same scale performed by the checkers provided 2.93 g (82%) of the product.

18. Crude

3-methyltetrahydrofuran-2-ol (

2) is stored at -20 ℃ in a sample vial sealed with parafilm, until use in the next step.

19. The checkers used

acetic acid (99.7%) purchased from VWR Chemicals BDH, which was used as received. The submitters used

acetic acid (99.7%) purchased from Fisher Chemical, which was used as received.

20. The checkers used

phenylhydrazine (

3) (>98%) from Merck-Schuchardt OHG, which was used as received. The submitters used

phenylhydrazine (

3) purchased from Oakwood Chemical, which was used as received.

21. The checkers performed this reaction open to air. The submitters ran the reaction after flushing the system with

nitrogen for 5 min and under an atmosphere of

nitrogen for the duration of the reaction.

22. The progress of the reaction is monitored by TLC analysis on silica gel plates using 5:1

hexanes:

EtOAc as the eluent. The plate is visualized using a phosphomolybdic acid stain. The lactol starting material (

2) has R

f 0.16 (UV inactive, blue-green) and the furoindoline product (

4) has R

f 0.43 (UV active, blue-black) (Figure 12).

Figure 12. TLC of the crude reaction mixture after 4 h (Sm = lactol 2, Rm = reaction mixture, and C = co-spot of Sm and Rm) (photo provided by checkers)

23. The checkers used

NaHCO3 purchased from Dieckmann Chemicals and used as received.

NaHCO3 (250 g) was added to 2000 mL of deionized water to make the saturated aqueous solution. The submitters used

NaHCO3 purchased from J. T. Baker, which was used as received.

24. The submitters quenched the reaction by adding the contents of the flask to 1500 mL saturated aqueous

NaHCO3 at room temperature with stirring. After adding additional portions of saturated

sodium bicarbonate solution (100 mL x 3) until the solution reaches a pH of 7, the contents of the flask are transferred to a separatory funnel (3000 mL), along with

ethyl acetate (2 x 50 mL) used to rinse the reaction flask. The aqueous layer is extracted with

ethyl acetate (3 x 250 mL).

25. The brine wash breaks up most of the emulsion formed, but the remaining emulsion is collected with the organic layer and dried by adding the

Na2SO4.

26. The checkers used activated charcoal purchased from ThermoFisher Scientific, which was used as received. The submitters used activated charcoal purchased from Fisher Scientific, which was used as received.

27. The checkers used celite purchased from Alfa Aesar, which was used as received. The submitters used celite purchased from Fisher Scientific, which was used as received.

28. The checkers used

hexanes (GR grade) purchased from Duksan Pure Chemicals, which was used as received. The submitters used

hexanes (98.5%) purchased from Sigma-Aldrich Corp., which was used as received.

29. The submitters prepared the silica gel column using 5:2

hexanes:

diethyl ether, and eluted the product using 5:2

hexanes:

diethyl ether (2000 mL), followed by 2:1

hexanes:

diethyl ether (2000 mL). The fractions are collected in 30 mL culture tubes and the desired product is found in fractions 41-86.

30. Fractions containing the product were identified by TLC analysis using 1:1

hexanes:

ethyl acetate as the eluent. The plates are visualized using UV and by phosphomolybdic acid staining. Furoindoline

4 has an R

f of 0.43 (UV active, blue-black). Fractions 38-64 contained the desired product, and each fraction is rinsed with (2 x 1 mL)

Et2O, to ensure quantitative transfer (Figure 13).

Figure 13. TLC plates showing column fractions (photo provided by checkers)

31. The submitters dried the product under a vacuum of <1 mmHg for 1 h.

32. The purified product (

4) is characterized as follows:

1H NMR

pdf (400 MHz,

CDCl3) δ: 7.10-7.02 (m, 2H), 6.75 (t,

J = 7.6 Hz, 1H), 6.58 (d,

J = 7.6 Hz, 1H), 5.27 (s, 1H), 4.56 (bs, 1H), 3.97-3.93 (m, 1H), 3.55 (ddd,

J = 11.4, 8.8, 4.7 Hz, 1H), 2.17 (ddd,

J = 12.0, 5.4, 1.6 Hz, 1H), 2.12-2.05 (m, 1H), 1.47 (s, 3H).

13C NMR

pdf (100 MHz,

CDCl3) δ : 148.9, 134.0, 127.9, 122.9, 118.9, 108.2, 99.6, 67.4, 53.8, 41.5, 24.7 ppm; IR (neat): 3360, 2951, 1489, 1215, 1036 cm

-1; HRMS-ESI (

m/z) [M+H]

+ calcd for C

11H

14NO, 176.1075; found, 176.1068; mp 39-41 ℃; R

f (1:1

hexanes:

EtOAc) 0.71.

33. The purity of

3 was determined to be 98.5% by qNMR

pdf using

1,3,5-trimethoxybenzene (Sigma-Aldrich, >99.9%) as the internal standard.

34. A second reaction performed by the checkers on the same scale provided 3.76 g (61%) of

4 of 98.6% purity.

Working with Hazardous Chemicals

The procedures in

Organic Syntheses are intended for use only by persons with proper training in experimental organic chemistry. All hazardous materials should be handled using the standard procedures for work with chemicals described in references such as "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at

http://www.nap.edu/catalog.php?record_id=12654). All chemical waste should be disposed of in accordance with local regulations. For general guidelines for the management of chemical waste, see Chapter 8 of Prudent Practices.

In some articles in Organic Syntheses, chemical-specific hazards are highlighted in red "Caution Notes" within a procedure. It is important to recognize that the absence of a caution note does not imply that no significant hazards are associated with the chemicals involved in that procedure. Prior to performing a reaction, a thorough risk assessment should be carried out that includes a review of the potential hazards associated with each chemical and experimental operation on the scale that is planned for the procedure. Guidelines for carrying out a risk assessment and for analyzing the hazards associated with chemicals can be found in Chapter 4 of Prudent Practices.

The procedures described in Organic Syntheses are provided as published and are conducted at one's own risk. Organic Syntheses, Inc., its Editors, and its Board of Directors do not warrant or guarantee the safety of individuals using these procedures and hereby disclaim any liability for any injuries or damages claimed to have resulted from or related in any way to the procedures herein.

3. Discussion

Fused indolines are found in a number of bioactive compounds, making them a privileged chemical motif. The importance of indoline-containing compounds has spurred the development of various methods to access them. Historically, fused indoline ring systems have been accessed from cyclization reactions of substituted indoles

2 or oxindoles

3. However, these methods pose regio- and diastereoselectivity challenges, and often possess long, linear synthetic sequences. The interrupted Fischer indolization offers a convergent approach to accessing these scaffolds. Furthermore, the transformation proceeds with excellent regio- and diastereoselectivity, while utilizing readily available starting materials.

4The interrupted Fischer indolization has been leveraged to access a variety of bioactive natural products and other compounds of medicinal interest. Several examples focusing on furoindolines are shown (Figure 14). Potential Alzheimer's therapeutic

5 was discovered in a structure-activity relationship (SAR) study to identify a dual inhibitor of nSMase2 and AChE, two proteins invoked in Alzheimer's disease pathology.

5 Furthermore, complex natural products bearing the fused indoline motif have been synthesized using the interrupted Fischer indolization, including aspidophylline A

6 (

6) and picrinine

7 (

7), as well as other natural products.

8 Through these and other examples, the interrupted Fischer indolization has proven to be a valuable tool for accessing biologically-relevant fused indoline scaffolds.

Figure 14. Selected applications of the interrupted Fischer indolization to access fused indolines

This procedure provides access to fused indoline scaffolds in one step from a hydrazine (

8) and the readily accessible latent aldehyde (

9) (Figure 15). Beyond the procedure demonstrated here, the method is tolerant of many functional groups, including substituents around the aryl ring of the hydrazine (

11,

4,

12,

13).

4 Furthermore, variation of the masked aldehyde to form five- and six-membered fused oxygen- and nitrogen-containing rings has been demonstrated (

14,

15,

16,

17).

4 Lastly, the interrupted Fischer indolization has also been used to access enantioenriched products via methods that utilize chiral acids and chiral auxiliaries.

4Figure 15. Selected scope of the interrupted Fischer indolization with respect to the hydrazine and masked aldehyde

4Overall, the interrupted Fischer indolization offers a rapid and efficient method for building fused indoline motifs. Its operational simplicity, convergency and scalability render the transformation an attractive alternative to other methods for the synthesis of fused indoline products. This methodology has been instrumental in accessing complex and bioactive compounds, including natural products that contain the furoindoline scaffold. The further development of this powerful methodology should allow the synthetic community access to valuable, medicinally relevant scaffolds.

Appendix

Chemical Abstracts Nomenclature (Registry Number)

3-Methyldihydrofuran-2(3H)-one; (1) (1679-47-6)

i-Bu2AlH (1.0 M in hexanes); (1191-15-7)

Phenylhydrazine; (100-63-0)

Acetic acid; (64-19-7)

|

Georgia Scherer was born and raised in Oakland, California. In 2020, she received her B.A. in Biochemistry from Claremont McKenna College where she performed research in the lab of Professor Ethan Van Arnam. In 2021, she began graduate studies at the University of California, Los Angeles, where she is currently a second-year graduate student in Professor Neil K. Garg's laboratory. Her studies primarily focus on developing synthetic methods utilizing strained cyclic allenes. |

|

Jordan Gonzalez was born and raised in Chandler, AZ. In 2021, he received his B.A. in Chemistry and Mathematics from Lewis & Clark College where he carried out research under the direction of Professor Louis Y. Kuo. In 2021, he began graduate studies at the University of California, Los Angeles, where he is currently a second-year graduate student in Professor Neil K. Garg's laboratory. His dissertation studies are primarily focused on total synthesis. |

|

Laura Wonilowicz was born and raised in Westminster, MD. In 2019, she received her B.S. in Biochemistry and a B.A. in Chemistry from Virginia Tech, where she carried out research under the direction of Professor Webster L. Santos. She began her graduate studies at the University of California, Los Angeles, where she is currently a fourth-year graduate student in Professor Neil K. Garg's laboratory. Her studies primarily focus on total synthesis and synthetic methods using strained cyclic allenes. |

|

Neil Garg is the Distinguished Kenneth N. Trueblood Professor of Chemistry at the University of California, Los Angeles. His laboratory develops novel synthetic strategies and methodologies to enable the total synthesis of complex bioactive molecules. |

|

Yu-Hin Ho obtained his Ph.D. in 2022 at The University of Hong Kong, under the supervision of Prof. Pauline Chiu. He is currently working as a researcher in the group. His research projects are on the total synthesis of natural products and other bioactive compounds. |

|

Zengsheng Yin obtained his Ph.D. from Donghua University in Shanghai in 2010, under the supervision of Prof. Feng-Ling Qing. He joined Prof. Chiu's group as a postdoctoral researcher, working on the total synthesis of natural products. |

Copyright © 1921-, Organic Syntheses, Inc. All Rights Reserved